Sheet Store

Extra Heavy Duty Automated Storage System

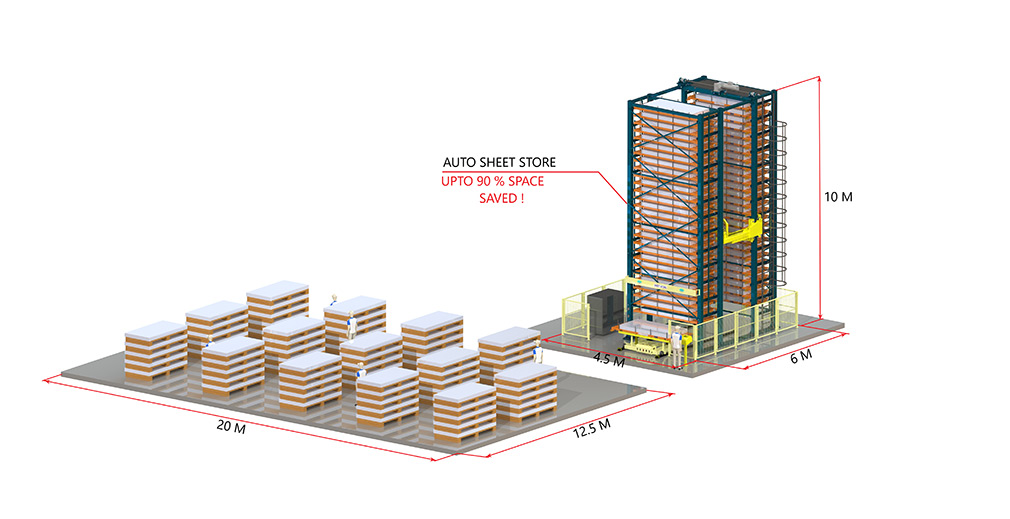

The Sheet Store is a robust and fully automated storage system designed for heavy-duty applications. By utilizing vertical space effectively, it minimizes the required floor space. By delivering the goods directly to the operator, this system reduces the risk of damage to raw materials and improves productivity.

This system is specifically designed for storing various items such as sheets (with or without bundles), moulds, dies, bar coils, and more. It offers efficient and organized storage solutions for a wide range of materials in an optimized footprint.

Technical Specification

| Cassette Dimensions | Length (mm) | Up to 6200 | |

| Width (mm) | Up to 2000 | ||

| Load Capacity Per Shelf (kg) | Up to 5000 | ||

| System Height (mm) | 12,000 | ||

| Max Live Load (kg) | 180,000 | ||

Metafold is the first Indian company to introduce this product into Indian market in 2015. Now in its fourth generation of design, Metafold has successfully commissioned over 25 systems across India and internationally.

Advantages

Safe

- Reduced risk of damages to material and injuries

- Pallet safety during storage in location is ensured by wheel stoppers

- Stopper pins are provided to safeguard sheets stored to avoid damage due to sliding

- Safety barrier to avoid unauthorized entry in access area

- Over load detection system is use of lift is overloaded with material

Efficient

- Organized and quick storage and retrieval of sheet metal

- Material change over time reduced to larger extend

- Instead of fork lift, cranes also can be used to load and unload the material

- Automatic and faster access to different pallets with higher work efficiency

Save

- With excellent space utilization, it lowers floor space up to 90% with smaller footprint

- Time saving due to direct automated access with out addition lifting devices

- Reduced operational costs and adds bottom line earnings

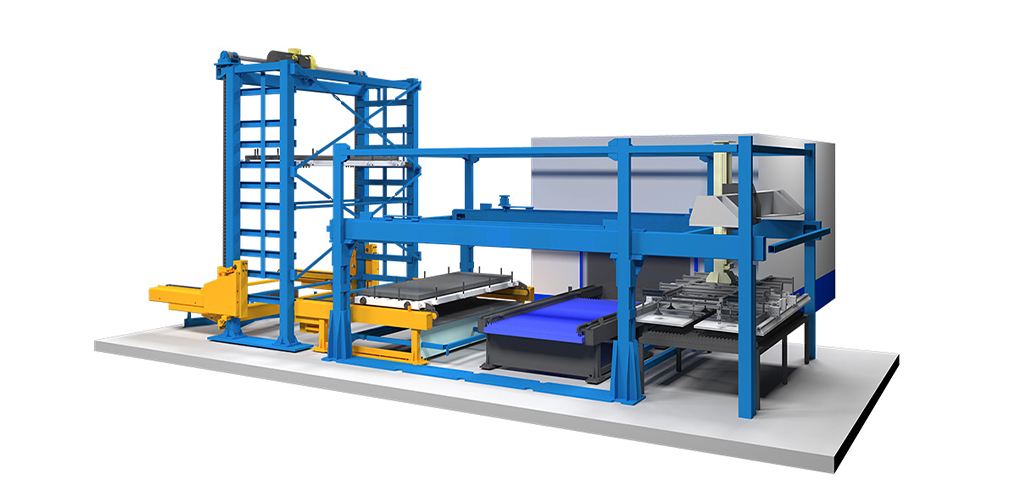

Automated Plate Loader System

Companies in Sheet Metal business, always faces challenges

- Storage of Raw Material

- Material movement from the storage space to the Laser Bed

- Picking and Sorting of Cut pieces from Laser Bed to Sorting Table

- Space required for manual material movement

- Higher cycle time due to dependency on manual operation

Our Sheet Store integrated with an Automated Plate Loader System provides a comprehensive solution to above challenges

Raw Sheets are lifted using the vacuum cups, while the processed sheets are lifted by fingers spanning all over the length of the sheet. To lift the sheet from the laser bed, the fingers are designed to fit into the toothed bed gap, raising the entire processed sheet from underneath. This design prevents cut pieces on the sheet from falling during material movement.

The Girder motion is guided on the Linear motion guide and rack and pinion rail and is controlled by a Servo Motor. This approach ensures that the lifting bed always remain aligned with the storage pallet and the laser bed. Due to this confirmed alignment, the horizontal travel speed of the girder reaches 60m/min.

Technical Specification

| Payload (kg) | 250 kg |

| Boom/LT Travel, Length (mm) | As per requirement |

| Vertical Lift of the Sheet from Base (mm) | 700 |

| Finger Metallurgy | Aluminium Extrusions |

Features

Unlock Efficiency

Unlock Efficiency

Fault Removal

Fault Removal

Sturdy and Robust Build

Sturdy and Robust Build

Precision Loading for Enhanced Accuracy

Precision Loading for Enhanced Accuracy

High-Speed Operation for Optimal Utilization

High-Speed Operation for Optimal Utilization

Versatile Handling of Large Plates

Versatile Handling of Large Plates

Metafold Engineering Pvt. Ltd.

- Warehousing Solution

- Automated Storage Solutions

- Industrial Storage System & Office Furnitures

- Roll – Out Storage Solutions

Quick Links

Head Office / Plant

Punyadham Ashram Road,

Pune - 411 048.

Business Hours

Sunday Closed

- Pune

- Mumbai

- Delhi

- Chennai

- Bangalore

- Surat

- Ahmedabad

- Hyderabad

- Kolkata

- Lucknow