Pipe Store

Long Span Goods Automated Storage System

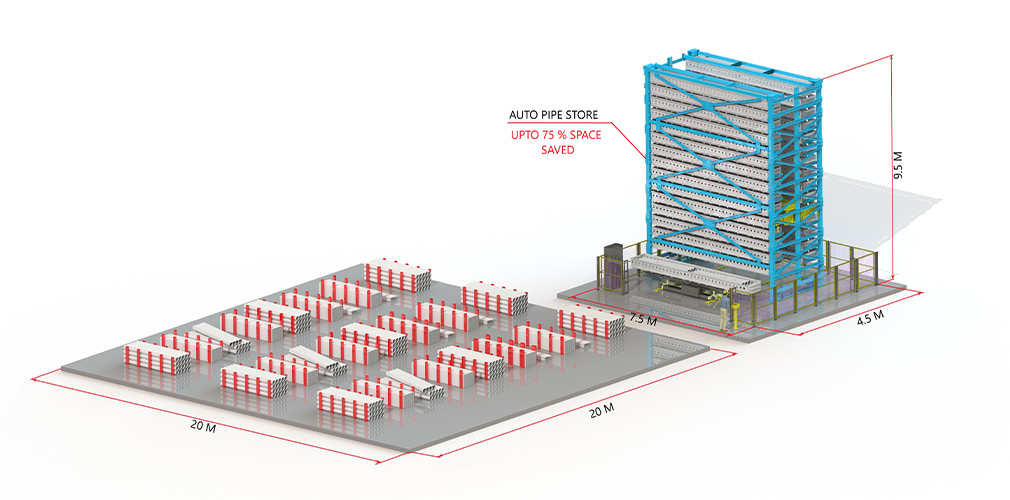

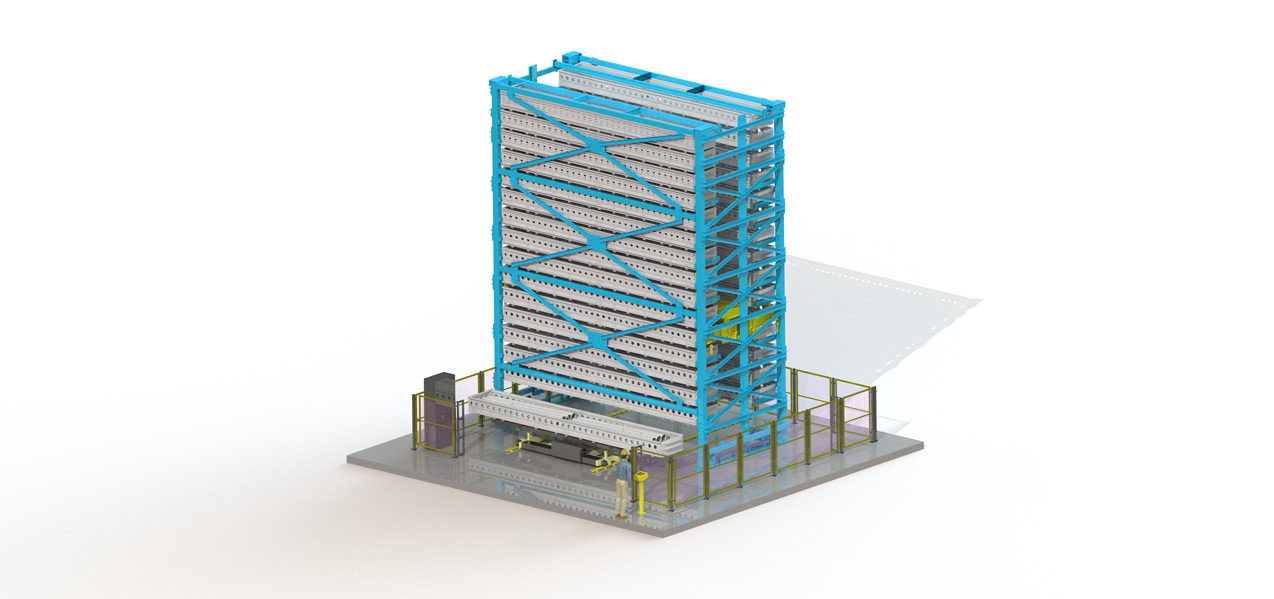

Pipe-Store is an advanced and robust automated storage and retrieval system designed specifically for the storage of lengthy materials such as pipes, bars, tubes, billets, aluminium extrusions, commercial sections, and more. This innovative system utilizes vertical space efficiently, allowing for maximum capacity while occupying a smaller footprint compared to traditional block storage methods.

The Pipe-Store operates based on the "goods-to-person" concept, which significantly reduces the risk of damage to raw materials and enhances productivity, by delivering the goods directly to the operator. The Pipe-Store eliminates the need for manual searching and retrieval and thus saving valuable time and minimizing the potential for material damage, particularly in the case of round pipes.

Given the constant rise in the land prices and the increasing manufacturing capacity throughout India, it has become essential to capitalize in seamless and secure handling of raw materials, optimizing operational efficiency and preserving the integrity of the materials.

Technical Specification

| Cassette Dimensions | Length (mm) | Up to 6200 | |

| Width (mm) | 550, 850 | ||

| Load Capacity Per Shelf (kg) | Up to 2500 | ||

| System Height (mm) | 10,000 | ||

| Max Live Load (kg) | 90,000 | ||

Metafold is the first Indian company to introduce this product into Indian market in 2019. Now in its third generation of design, Metafold has successfully sold over 25 systems across India.

Companies face significant challenges when it comes to storing and sorting materials, particularly with:

- Managing large quantities of pipes exceeding 100 tons.

- Addressing rust issues caused by improper material storage.

- Tackling bowing in pipes due to uneven storage methods.

- Handling a wide variety of SKUs with variations in outer diameter, inner diameter, length, and metallurgy

To mitigate the above challenges, our Back-to-Back systems with a shared feeder and extractor trolley provide a comprehensive solution for your storage needs.

Many OEMs have restrictions on the presence of EOT in the installation area. Our system is crafted to address this limitation. To facilitate smooth material movement, EOTs can be easily and cost-effectively integrated with the system.

Advantages

Efficient

- Organized and quick storage and retrieval

- Material change over time reduced to larger extend

- Instead of fork lift, cranes also can be used to load and unload the material

Safety

- Heavy Duty Design

- Seismic-resistant structure

- Safety flange to secure cassette in its designated location

- Machine Safety Light Curtain

Operations

- Material extraction at either or both side of system

- Multiple access points as per customer requirement

Safe

- Reduced risk of damages to material and injuries

- Safety barrier to avoid unauthorized entry in access area

- Over load detection system is use of lift is overloaded with materia

Save

- Reduce floor space required by 75%

- Time saving due to direct automated access with out addition lifting devices

- Reduced operational costs and adds bottom line earnings

Metafold Engineering Pvt. Ltd.

- Warehousing Solution

- Automated Storage Solutions

- Industrial Storage System & Office Furnitures

- Roll – Out Storage Solutions

Quick Links

Head Office / Plant

Punyadham Ashram Road,

Pune - 411 048.

Business Hours

Sunday Closed

- Pune

- Mumbai

- Delhi

- Chennai

- Bangalore

- Surat

- Ahmedabad

- Hyderabad

- Kolkata

- Lucknow